Rig and Spar Design

- Stability Studies

- Rig and Spar Design

- Stabilizer Systems

- Powering and Systems

- Structural Modifications

Consulting takes many forms, it may involve getting my opinion on a particular boat or project or it may include planning or concept sketches and design drawings of a required modification.My work in consulting involves studies of powering, stability, control, motion, construction and arrangements. Small craft are generally anything under about 150' in length. Most of my current work concerns boats 24m and under. I work closely with associated experts including my colleagues in B.C. at CR Engineering.

Consulting takes many forms, it may involve getting my opinion on a particular boat or project or it may include planning or concept sketches and design drawings of a required modification.My work in consulting involves studies of powering, stability, control, motion, construction and arrangements. Small craft are generally anything under about 150' in length. Most of my current work concerns boats 24m and under. I work closely with associated experts including my colleagues in B.C. at CR Engineering. 2016/03/ Current Stability Projects as of March 2016:

- Bellacra Explorer Stability Study

Fast aluminum craft, stability study following successful completion of my recommendations for structural modifications to improve performance

- Majestic Warrior Stability Study Commercial Fish Packer

- Northern Dream Stability Study and Design Modifications for Pilot House 120' Motoryacht

- IV Interceptor Stability Study 36' Commercial Troller

- Leeway Stability Study 40' Schooner

- T1 Stability Study 100' by 25' Landing Craft

- Content Stability Study 60' Motoryacht

-

Rig and Spar Design

Rig and Spar Design

We have done a number of these including a new mainmast for the Canadian Navy sailing vessel Oriole, designing a cutter rig for a Kettenburg 40, a new rig for a Cape George 31 including mast design, a two spreader rig wooden spar and rig for the Swain 36, and a schooner junk rig for an Allied Princess 36.

A new mainmast for the 102' (31 m) Canadian Navy sailing vessel HMCS Oriole: In the case of Oriole’s new mainmast, it was a replacement wooden spar, but we probably saved 100 pounds with a new aluminum masthead fitting.

A new mainmast for the 102' (31 m) Canadian Navy sailing vessel HMCS Oriole: In the case of Oriole’s new mainmast, it was a replacement wooden spar, but we probably saved 100 pounds with a new aluminum masthead fitting.

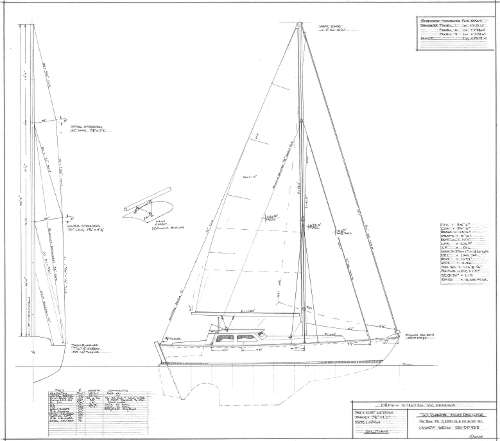

Changing the rig or even revising the existing rig can transform a boat into something new. In one case I re-designed the rig and deck hardware layout in a Kettenburg 41, changing her from a sloop to a cutter. In the owner’s view this made the boat far more manageable as when the wind increased they just rolled up the jib and proceeded under main and staysail. In other cases I have designed new, lighter rigs which make the boat faster and stiffer.

Currently, we are consulting on a new rig for a 50' Frank Fredette sailing troller.

Currently, we are consulting on a new rig for a 50' Frank Fredette sailing troller.

-

We have considerable experience with classic and traditional sailing yachts to 154', with expertise in rigging and deck design, spar and rig design, and deck layout for efficiency. Recently we were consulted on rig changes to Whitefin, a 90' BKYD sloop.

We have considerable experience with classic and traditional sailing yachts to 154', with expertise in rigging and deck design, spar and rig design, and deck layout for efficiency. Recently we were consulted on rig changes to Whitefin, a 90' BKYD sloop.

Designing a Wooden Spar

Every material can be bent or distorted a certain amount and still spring back to its original shape. Every material also has a limit of loading beyond which it will be permanently distorted (bent or broken). This is referred to as the Elastic Limit, the usual symbol for this is E, and it’s a number in psi or Kilonewtons/mm2 or Gigapascals (GPa). For example:

- E for Aluminum is 10 * 10^6 = 10,000,000 psi

- E for Sitka Spruce is 1.57 * 10^6 = 1,570,000 psi

- E for Douglas Fir is 1.95 * 10^6 = 1,950,000 psi

- E for Red Cedar is 1.12 * 10^6 = 1,120,000 psi

-

Power: Masts and Stabilizer Poles, Auxillary Sails

Spar and rig design also includes masts and adding sails or stabilizer poles to power vessels.

The addition of sails as stabilizers and get home propulsion is a concept which I believe is under-utilized. Most powerboats have opted for very complex rigs (derived from racing rigs) with expense and maintenance all out of proportion to their use. This is an area that needs more work.

A new ketch-rigged 62' aluminum Passagemaker Lite in the 02 series is in development. The sailing rig is designed to be folded down by the owner and kept aboard during canal cruising. It will be the largest of our current sail-assisted power designs, the Timbercoast Troller 22, Garden Bay 23, Wedge Point 27, Northcoast 34, and Ocean 55.

- Read more on the Stabilizer Systems and Auxillary Sails page >>

-

Alternative Rigs

Alternatives to the high-aspect, high stress, high-expense Marconi masthead sloop or cutter are numerous. Standing Lug, dipping Lug, Chinese Lug, Balanced Lug, ketch, schooner, cat yawl, the list goes on.

Most are popularly maligned due to vested interests or plain ignorance. Relatively few folks have sailed anything other than a sloop or a cutter, yet because the Broker told them it was “the best”, that’s what they continue to sail. And they struggle to maintain all the high stress parts, struggle to control the oversize and hard to reef sails, and struggle to control the boat in higher or changing winds.

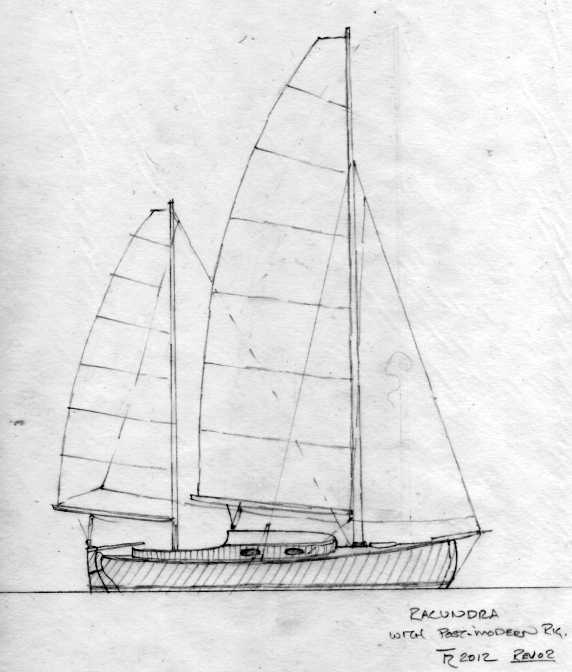

Recently I’ve been working on two replacement alternative rigs for stock production fiberglass boats. The first is a un-stayed lug schooner (with jib) rig for a dismasted Wright-Allied Princess 36 ketch designed by Arthur Edmonds. The owner, Daniel Collins, has a detailed account of the rig change at his blog, oddasea.com. The new rig is also written up as a Junk Rig Association's Boat of the Month, JRA Mag. #62, August 2013.... The other replacement alternative rig is a Split Chinese lug for a Columbia 36 designed by Bill Crealock.

The reasons for interest in these alternative rigs are various. The first is there are now numerous examples of them sailing around. This happened over many years work by determined (mostly) amateur designer/builders, few professionals would touch the subject because major builders were not interested. Phil Bolger was one professional who worked hard to simplify cruising rigs. Another reason for interest in alternatives is that 1970s-80s production boats are 30+ years old and their aluminum sloop rigs are getting tired. People are finding out that a new sloop rig will cost them $30k and the boat is still only worth $15k. So they are looking for a rig they can build for themselves. And many sailor’s are getting older and finding it’s no fun to struggle with a sticky main while balanced on the cabintop or dealing with flailing sheets and an override on a big winch. These large sloop/cutter rigs are a lot of work, many are designed to be worked by a 6-8 person crew. The sails are work, it’s a bit scary when things happen fast, and heeling isn’t much fun for long, and so they don’t get used. I see boats powering upwind and down even on beautiful sailing days.

Smaller individual sails, very low sheet loads (no winches), simple (one-handed) reefing and lowering, less heel due to lower COE, simple parts you can make yourself, and lower cost due to simpler/fewer parts. These are the positives. The biggest negative will be reduced windward performance; generally the boat will not point as high. Also you may have to work harder at spreading adequate sail area in light air. Usually a big drifter/stay’sl set flying will do it. On a given hull over a day’s sailing you will end up about the same as the standard sloop/cutter. This is because there is much more involved that just the rig choice. Hull form, resistance, crew, navigation, and tactics all play a part in how far you sail each day.

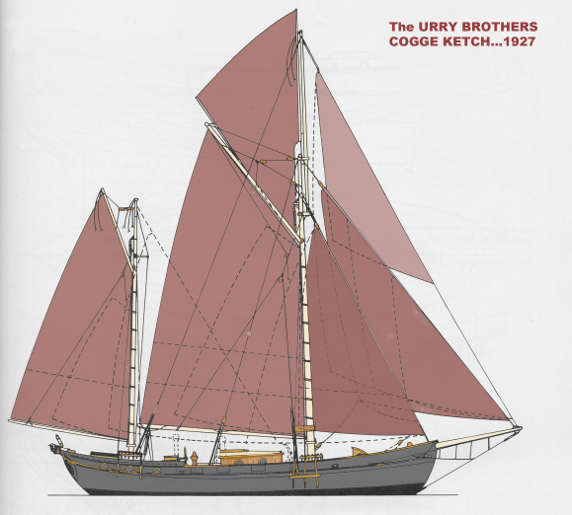

Un-stayed lug schooner (with jib) rig for a dismasted Wright-Allied Princess 36 ketch designed by Arthur Edmonds.

The schooner rig was designed by Tad Roberts, of Gabriola Island, BC, to complement the stout Princess hull with its cutaway full keel and shallow 4.5' (1.4m) draft. To move the 16,000 lb (7.25 metric ton) hull smoothly through the water, Tad specified nearly 660 square feet (61 sq. m) of sail area in two nearly equal-sized sails. The masts are aluminum streetlamp poles and are unstayed, although running backstays are fitted for belt-and-suspenders reliability in a rough sea or when flying staysails. Junk Rig Association's Boat of the Month, JRA Mag. #62, August 2013...